Solfina

FILTER SYSTEM

FILTER SYSTEM

The most efficient way to fry

1

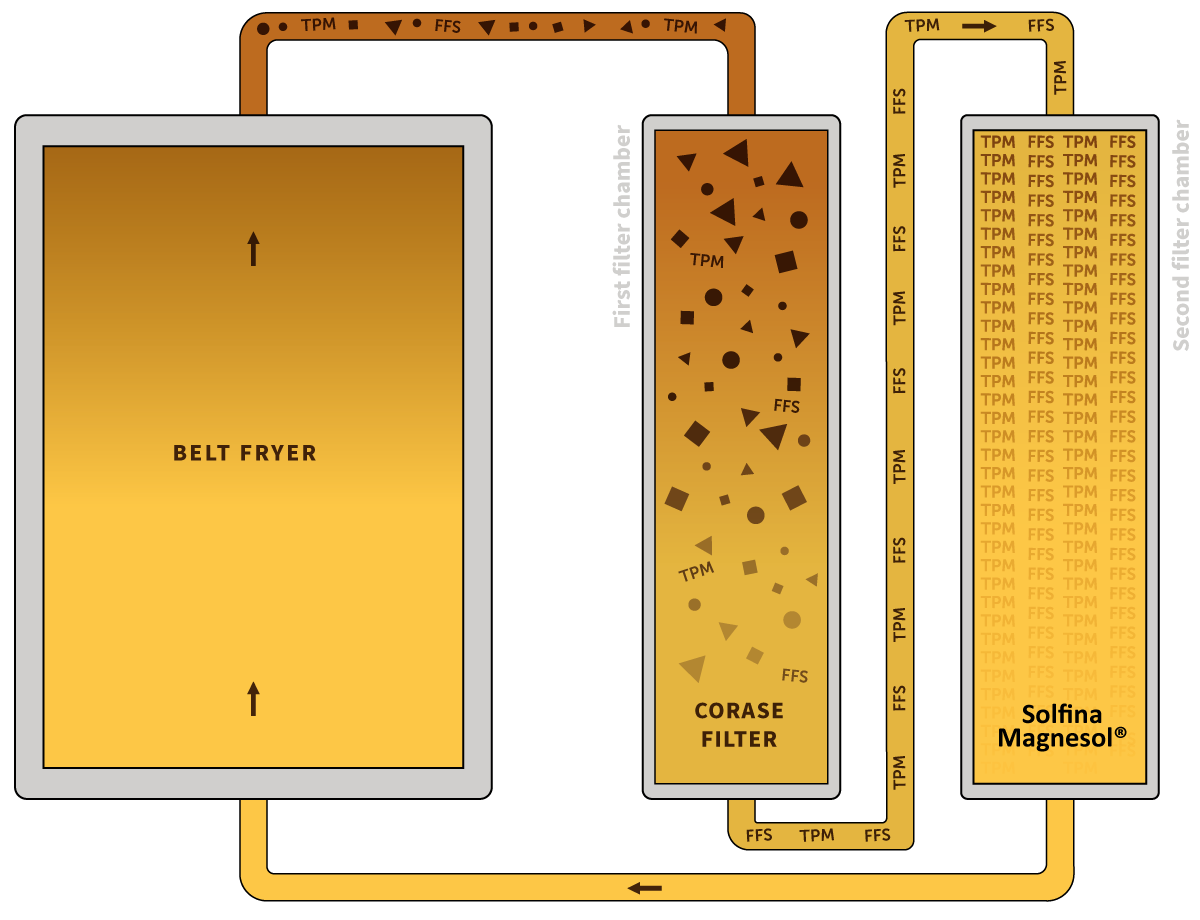

Coarse filter stage

Coarse contaminants such as unused breadcrumbs, crumbs, spices, herbs, carbonised residues etc. are filtered out in the first chamber.

2

Fine filter stage

In the second chamber, with the aid of the filter medium Magnesol®, we efficiently filter out fatty acids, polar compounds and metals from your oil or fat.

Solfina

Magnesol®

Magnesol®

Thanks to its numerous positive characteristics, our main filter medium Magnesol® is suitable for a broad range of applications. The powder made from magnesium silicate binds substances causing fats to degrade; they are drawn to it like a magnet. The powder itself is inert and heat-resistant. It can be removed from the oil or fat without leaving any traces and can therefore be safely used with food products.

Guaranteed functional efficiency

We don’t install systems at your production facility and then leave you alone to get on with it. We are only satisfied when the defined targets and results have been reached.

All-round hassle-free service

Our specialist calculates your actual requirements in terms of filter media and takes into account your production plans. If you prefer, we can supply you with new filters even before you run out of them. However, if you ever need a greater number of filters or have too many, it goes without saying that we can adjust the amount supplied.

Ideal for the following sectors

Bakeries

Food production

Biodiesel

Butchers

Catering

System catering

Cantines

Hotels

Hospitals

The right solution for your business

Select your business and go directly to the information specifically tailored to your sector.

Request a non-binding consultation now and optimise frying processes.

Your time is precious, so don`t waste time waiting with your call on hold. We’ll be happy to call you back.

Danke für Ihre Kontaktaufnahme!

Peter Wicki

Managing director

CH/FL: +41 81 756 02 48

EU: +43 72 0514 072

Would you prefer to contact us directly?

Just reach out to my team.