Modern frying is

efficient, sustainable

and cost-saving.

efficient, sustainable

and cost-saving.

Frying in

food production

food production

Solfina has solutions for industries where food is fried and which are keen to achieve high quality standards while keeping costs low and operating sustainably.

We optimise your frying quality

With the aid of our very own two-stage filter system we are able to consistently improve the quality of frying oil or fat. During the first stage coarse particles are filtered out, the second stage is fitted with the appropriate filter medium, to catch and reduce fatty acids, polar compounds, metals and water, these are captured in the filter medium. You achieve best results over multiple batches

- Binds fatty acids and polar compounds

- Reduces metals and other chemical compounds

We minimize your oil consumption

With our patented filter media such as Magnesol® we can consistently remove elements causing fat to spoil from your oil or fat without leaving any residues. Through the natural technical process, fatty acids only build up slowly and your oil lasts much longer. You reduce your oil consumption considerably and you protect the environment, sending out a strong message against food waste.

- Hardly any used oil or none at all

- Strong message against food waste

Shorter downtimes

Our filter system filters 1000 litres of frying oil or frying fat per hour, thus preventing slag which causes fat to spoil from building up at the bottom of your fryer. Given that even carbonised residues cannot be reincorporated into oil, there are considerably longer intervals between cleaning operations. Your production downtimes are reduced and you save valuable resources.

- Longer intervals between cleaning for your fryer.

- Reduced downtimes in production

We lower your costs

We work hand in hand with our customers and have recognised the need for competitive systems capable of paying for themselves more quickly. Our systems are tailored to your business and manufactured so that they are as streamlined as possible. The permanent savings in the amount of oil consumed plus reductions in labour costs enable a quick return on investment.

- Attractively priced systems with a fast return on investments

- Reduced oil costs and personnel expenses

Less generation of smoke and odour emission

By reducing the saponification of the oil medium and sustainably enhancing its properties, the amount of smoke generated is considerably reduced. The high quality of the oil or fat throughout the day also has positive effects on the formation of odours: they are palpably reduced.

- Reduced formation of smoke

- Reduces fatty smells

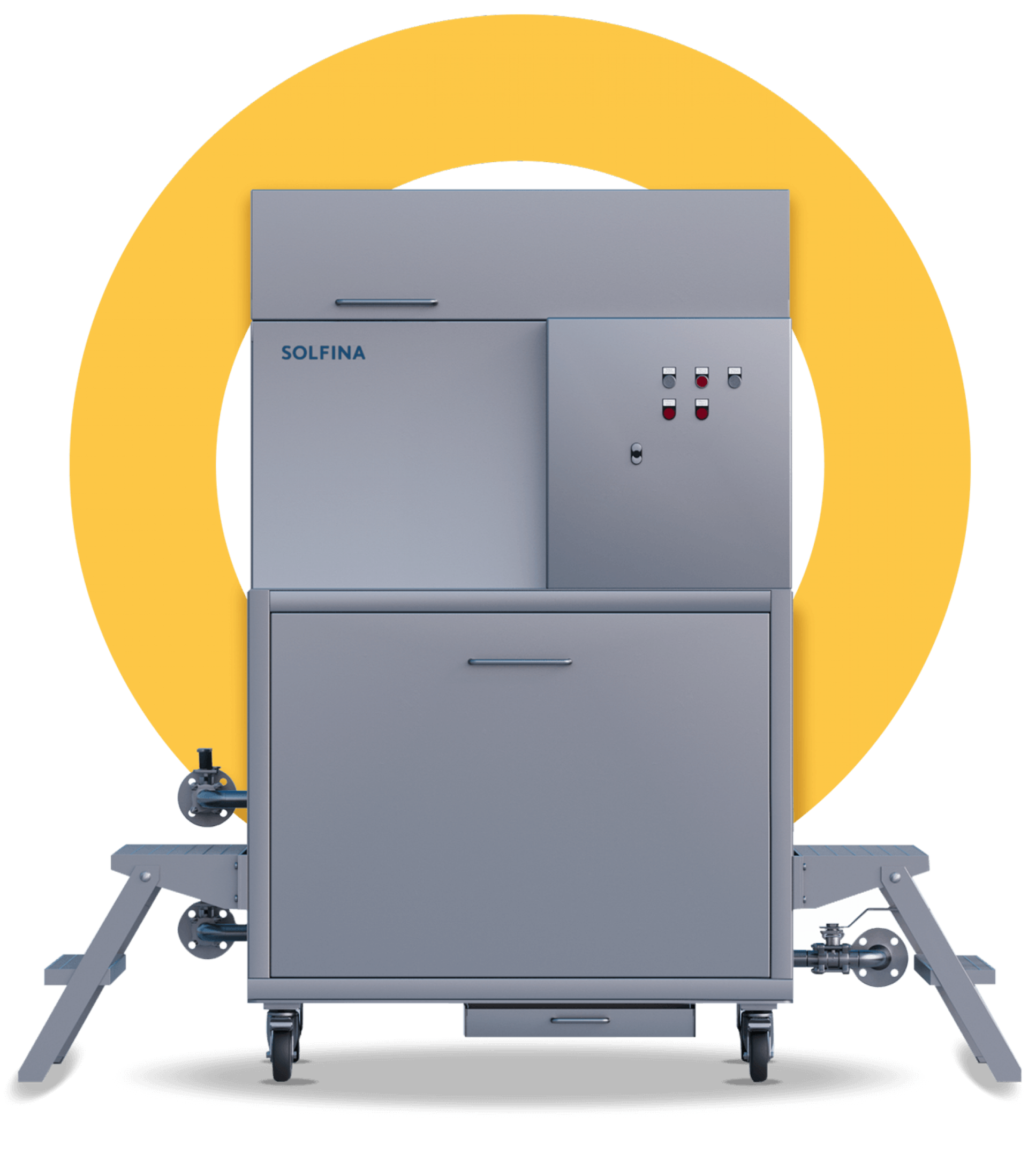

Two-stage

FILTER SYSTEM

FILTER SYSTEM

The perfect combination of coarse and fine filtration enables a systematic reduction in fatty acids and other substances causing fats to spoil. When deployed flexibly, this system is capable of ensuring consistent product quality.

- For fryers with 200 litre capacity or more

- Constant fine and coarse filtration

- Effectively binds substances causing fat and oil degradation.

Three steps to optimised frying processes

Analysis and consultation

Our specialists analyse your current situation and advise you on how you can optimise your production with the aid of our systems and processes.

Tailor-made solution

We design your system and determine the correct filter medium. You receive a tailored solution capable of meeting all your needs.

Commissioning

We supply a ready to go system and provide you with support until the system operates to your utmost satisfaction. We train your staff and keep your costs low.

Request a non-binding consultation now and optimise frying processes.

Your time is precious, so don`t waste time waiting with your call on hold. We’ll be happy to call you back.

Danke für die Kontaktaufnahme. Wir melden uns gerne bei Ihnen.